In 1982 the Hellenic Institute for the Preservation of Nautical Tradition (H.I.P.N.T) took a historic decision: to build an exact replica of the ancient ship of Kyrenia with the same dimensions as the original, with the same materials and even with the same methods relying not on indications or hypotheses but on scientific data which came to light with the raising and restoration of the ancient ship, thus embarking on the most serious venture of experimental archaeology in Greece and in the whole world: to build a model that would not lie in a museum but one that would sail across the Greek seas, just like the ancient original.

This undertaking was, of course, far from easy. It took scientists, archaeologists, shipmakers and boat builders three years to complete the project. Above all it required perseverance and commitment on the part of the men working at the Hellenic Institute for the Preservation of Nautical Tradition. These men did not give up even when they were assured by specialists that such an attempt was almost impossible

.

The greatest difficulty was the fact that the ancient ship was built by employing a method that had been forgotten for ages, a shipbuilding technique that was used by Greek and Roman boat builders and abandoned between the 7th and 10th century because it required many hands and large quantities of timber. This method is known as "SHELL FIRST CONSTRUCTION", i.e constructing the outer shell first and looks so unorthodox to the modern shipbuilder that it has been likened to a tree whose trunk and branches are supported by the leaves.

Construction of Kyrenia II begins at Psarros shipyard, Perama. The first piece of wood to be used can be seen. From right to left: Ch. Tzalas - President HIPNT, Professor Katsev, M. Psarros, Y. Pantzopoulos - Gen. Secretary HIPNT.

So, in the autumn of 1982 work on building Kyrenia II began, aided by professors KATSEV and STEFFY with their rich background and traditional boat builders with their long experience.

So, in the autumn of 1982 work on building Kyrenia II began, aided by professors KATSEV and STEFFY with their rich background and traditional boat builders with their long experience.

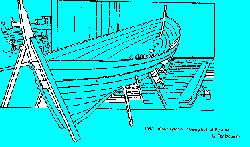

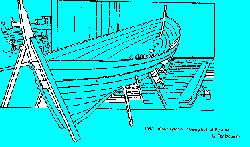

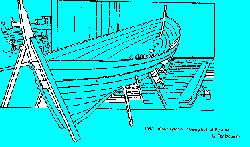

The keel, curved and not straight as in contemporary light fast sailing boats, was laid first.

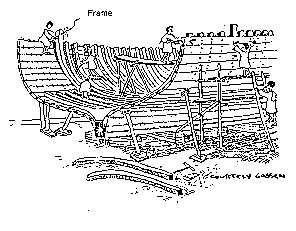

The beams were then put up, giving shape to the shell of the ship. There was no skeleton or frame - only a few signs here and there confirmed the correctness of the construction.

The beams were then put up, giving shape to the shell of the ship. There was no skeleton or frame - only a few signs here and there confirmed the correctness of the construction.

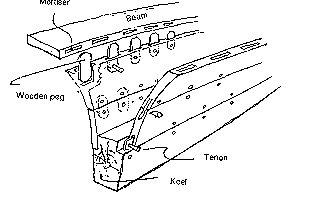

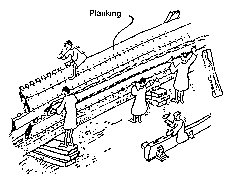

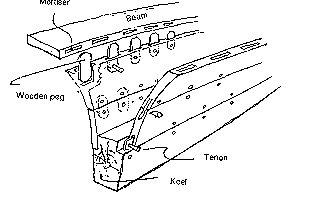

Starting from the keel, every beam was joined to the next with oak tenons, which were laid in square mortises carved out with a thin chisel. Thousands of oak tenons and wooden pegs secured the strakes together. About 4000 joints, 8000 mortises which accepted them and 4000 tenons secured the shell of the vessel.

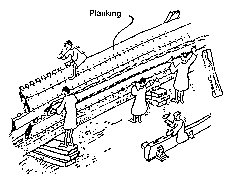

The first strake or plank followed the next and so on until the wooden shell of the ship rose from the keel without using a single nail.

The first strake or plank followed the next and so on until the wooden shell of the ship rose from the keel without using a single nail.

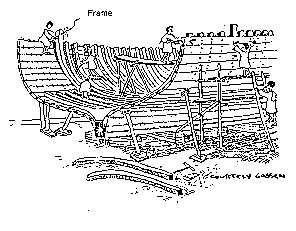

The wooden frame, like every piece of wood, was scraped with a lath- hammer until it took its final shape.

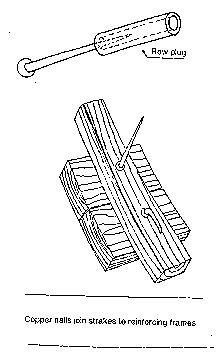

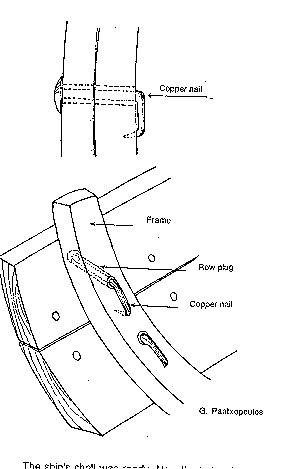

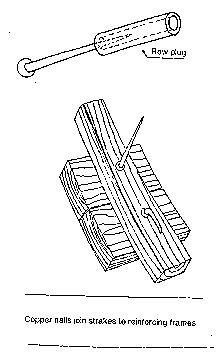

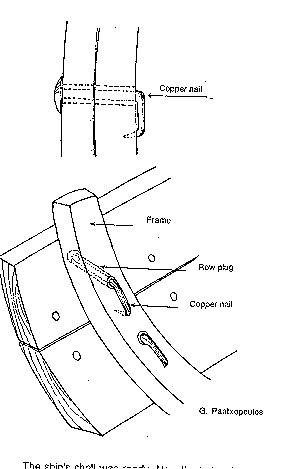

Measurements were taken and one by one the reinforcing curved frames were made and secured in the interior of the ship. 4000 holes with a 20 mm. diameter were drilled and an equal number of wooden plugs with 8 mm. holes in the middle - like wooden tubes - were interposed while handmade copper nails were hammered in with their tips bent and then clenched over to bite into the frame top.

Measurements were taken and one by one the reinforcing curved frames were made and secured in the interior of the ship. 4000 holes with a 20 mm. diameter were drilled and an equal number of wooden plugs with 8 mm. holes in the middle - like wooden tubes - were interposed while handmade copper nails were hammered in with their tips bent and then clenched over to bite into the frame top.

The ship's shell was ready. Now the bulwarks, the decks, the protective railings and the rigging had to be made. These were parts of the ship for which no corresponding sections had been found.

Every piece of information derived from ancient representations and reliefs that have been preserved was exploited for their construction. Use was made of the experience of boat builders, of the people who continue a centuries-old tradition and can, in a short time, think and act just like their ancient colleagues.

Every piece of information derived from ancient representations and reliefs that have been preserved was exploited for their construction. Use was made of the experience of boat builders, of the people who continue a centuries-old tradition and can, in a short time, think and act just like their ancient colleagues.

The rigging, which is a vital part of the ship, became the object of intense preoccupation and experimentation.

The rigging artisans contributed with their experience too. In their hands the thick hemp rope is a familiar and pliable material. Equally familiar to them are the pulleys they take in their hands, even though they are exact duplicates of those on the ancient ship.

The building of the replica was now completed. But before "Kyrenia II" set sail either for short or for long trips, it had to be painted for protection. Following the tradition of old boat builders and, perhaps, ancient craftsmen, every piece of wood was covered with wet pine-resin and fat. The parts that were exposed to water were painted black, using linseed oil not only for aesthetic reasons but also to protect the wood from sea worms and make it more water-resistant.

A short time before its launching, Kyrenia II acquired its only ornament. As was the custom in ancient times, two blue eyes that would gaze at the Greek seas and the marine routes of peace and civilization while it sailed along, were painted on either side of the bow.

Information mainly taken from text by YIANNIS PANTZOPOULOS, Gen. Secretary of the Hellenic Institute for the Preservation of Nautical Tradition (HIPNT).

Go back to the previous page

Monday, May 27, 1996 11:59:56 PM

So, in the autumn of 1982 work on building Kyrenia II began, aided by professors KATSEV and STEFFY with their rich background and traditional boat builders with their long experience.

So, in the autumn of 1982 work on building Kyrenia II began, aided by professors KATSEV and STEFFY with their rich background and traditional boat builders with their long experience. The beams were then put up, giving shape to the shell of the ship. There was no skeleton or frame - only a few signs here and there confirmed the correctness of the construction.

The beams were then put up, giving shape to the shell of the ship. There was no skeleton or frame - only a few signs here and there confirmed the correctness of the construction. The first strake or plank followed the next and so on until the wooden shell of the ship rose from the keel without using a single nail.

The first strake or plank followed the next and so on until the wooden shell of the ship rose from the keel without using a single nail. Measurements were taken and one by one the reinforcing curved frames were made and secured in the interior of the ship. 4000 holes with a 20 mm. diameter were drilled and an equal number of wooden plugs with 8 mm. holes in the middle - like wooden tubes - were interposed while handmade copper nails were hammered in with their tips bent and then clenched over to bite into the frame top.

Measurements were taken and one by one the reinforcing curved frames were made and secured in the interior of the ship. 4000 holes with a 20 mm. diameter were drilled and an equal number of wooden plugs with 8 mm. holes in the middle - like wooden tubes - were interposed while handmade copper nails were hammered in with their tips bent and then clenched over to bite into the frame top. Every piece of information derived from ancient representations and reliefs that have been preserved was exploited for their construction. Use was made of the experience of boat builders, of the people who continue a centuries-old tradition and can, in a short time, think and act just like their ancient colleagues.

Every piece of information derived from ancient representations and reliefs that have been preserved was exploited for their construction. Use was made of the experience of boat builders, of the people who continue a centuries-old tradition and can, in a short time, think and act just like their ancient colleagues.